-

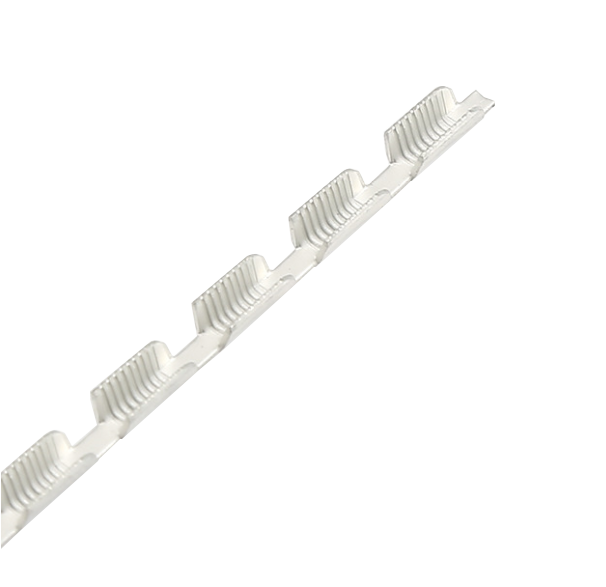

Dimensions and appearance requirements (staff self test)

1, wire preparation (in accordance with the requirements of the engineering drawings) test peeling length, wire length, wire damage.

2, check the expected length

3, conductor

A, crimp height, width and shape of crimping and samples had no significant difference;

B, tensile strength see "terminal tensile strength of the working procedure";

C, the conductor must be fully closed and contains the core line;

D, after the bell must be visible;

E, the end of the conductor must be flush, extending out of the area.

4, insulation skin pressing area

A, press the size and shape to press the wire without piercing as the standard;

B, swing test: hand from 76mm connector at the upper and lower bending 90 degrees, no loosening has been pressed, and then check the line without skin can be punctured;

C, in addition to the compression zone outside the skin without damage.

5, with the area of terminal shrapnel and no damage deformation

+86-13656777668

+86-13656777668