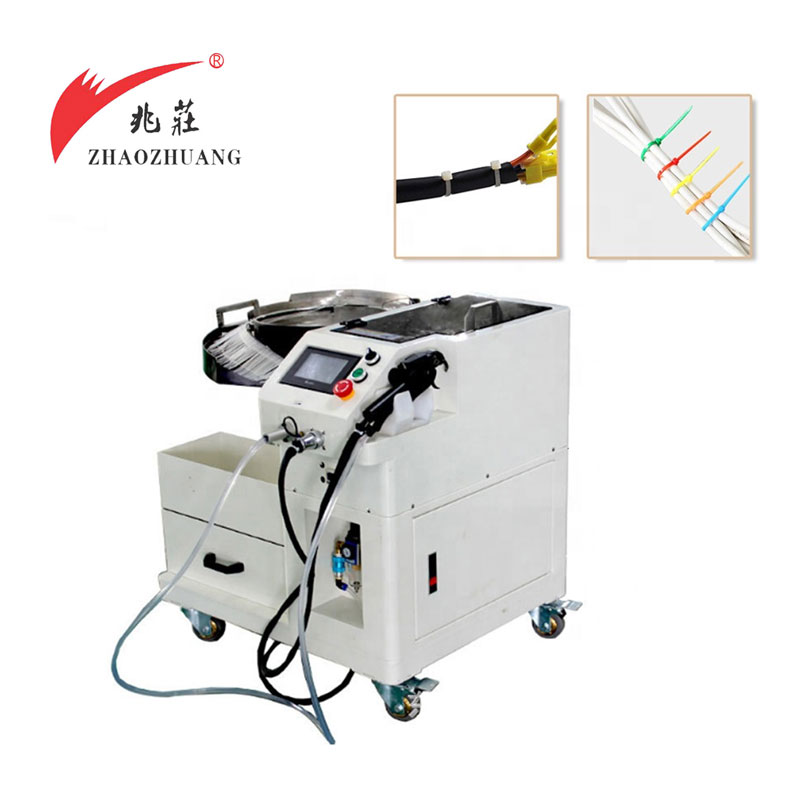

Hand-held Nylon Cable Tie Tying Machine

Product Categories: Winding and Bundling

Model: XC-390F

Brand: ZHAOZHUANG

Online InquiryFeatures:

1.The disordered bulk cable ties flow into random vibration plate, cable ties piped through to tips

2.Pull the trigger, automatic feeding, tape, tightening, cutting, polishing wastes and all other actions;

3.0.7 seconds to complete all actions including feeding, tape, tightening, cutting, polishing wastes, also including auxiliary time, the whole cycle a total of about 1.3 seconds.A machine can replace 7-8 workers. A year can save wage costs over 20 million;

4.Waste collected automatically in a waste box via a dedicated recovery system (optional);

5.Hand held tip lightweight ,compact design grip, easy to hold, long-term use will not feel tired;

6.Tying the intensity or tension can be adjusted by the knob;

7.Host body own PLC control system, touch screen Chinese /English display, simple operation;

8.In automatic production line can be conjunction with robot to achieve fully automatic cable tie,Also it can be fixed to the table using as the desktop cable tie machine.

|

Cable ties Specifications |

|

|

Minimum tie bundle diameter |

1mm |

|

The maximum wire harness diameter |

20mm |

|

The maximum beam tube diameter |

18mm |

|

Banding efficiency |

0.8 s/pcs |

|

Power supply |

Host body AC 220V 50 / 60Hz |

|

Hand held tips |

DC 24V (automatic translation) |

|

Barometric pressure |

5 Kg/ cm² |

|

Size |

L650*W550*H650 mm |

|

Hand held tips size |

220*85X*52mm |

|

Weight |

Host body 80 kg (With 4 wheels move easily) |

|

|

Hand held tips 1.1kg |

+86-13656777668

+86-13656777668